Would you also like to visit the Biesbosch MuseumEiland and basket maker Arie Versteeg? Here is a list of the locations Prisca visited:

- Biesbosch MuseumEiland, Hilweg 2 in Werkendam. There is ample parking and a charging point for electric bicycles. Especially in the winter period it is wonderful walking in the area. The peace and quiet is exceptional and along the way you will see many animals such as hares, different species of birds and you may encounter a diligent beaver.

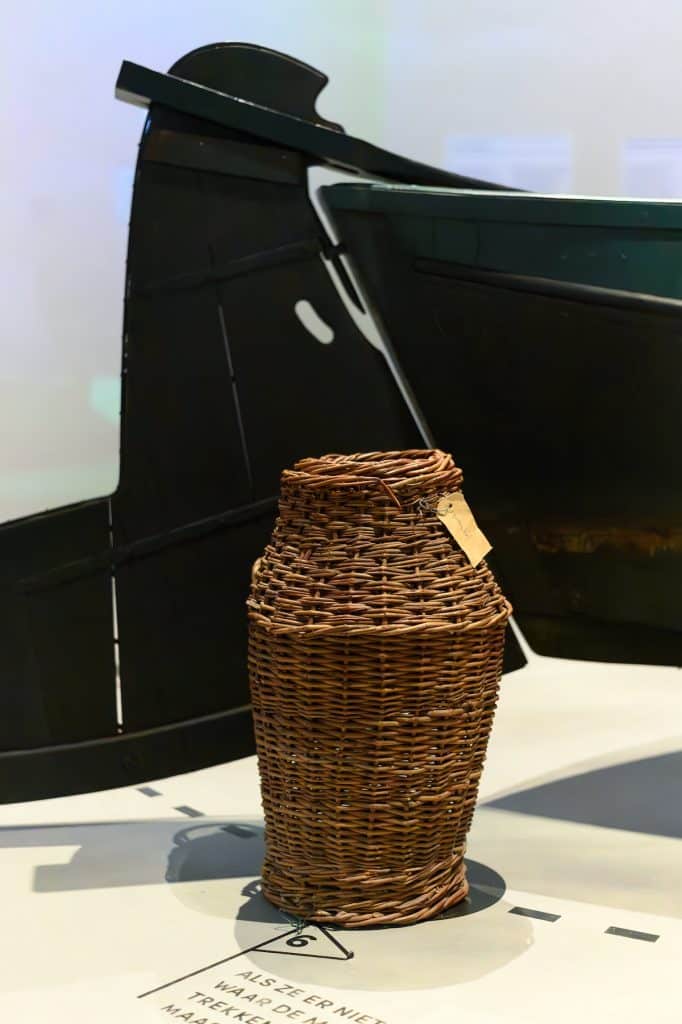

- Versteeg Baskets, Polstraat 19a in Wijk en Aalburg. In the store you will find a large selection of baskets, but you can also go there for custom orders.

Text and photos: www.priscavisser.nl. Here you will find all of Prisca's blogs.